Stand-up Pouches & Bags

Stand-up pouch packaging is one of the fastest-growing packaging formats.

Whether you’re in the food & beverage, nutritional & nutraceutical, household products, pet food, pharmaceutical, or personal care & cosmetic industry partner with us to create customized stand-up pouch packaging based upon your product’s unique formulation, usage, life cycle, and filling equipment.

LIFE CYCLE ADVANTAGES OF FLEXIBLE PACKAGING¹

Flexible packaging, when compared to other package formats, has preferable environmental attributes for carbon impact, fossil fuel usage, water usage, product-to-package ratio, as well as material to landfill.

¹ Source: Flexible Packaging Association, “A Holistic View of the Role of Flexible Packaging in a Sustainable World” Report, 2018

Stand-up Pouch Packaging Options

TruRenu PCR Pouches

Pouches with post-consumer recycled resin.

TruRenu Recyclable Pouches

Available in barrier and non-barrier formats.

Premade STANDCAP Pouch

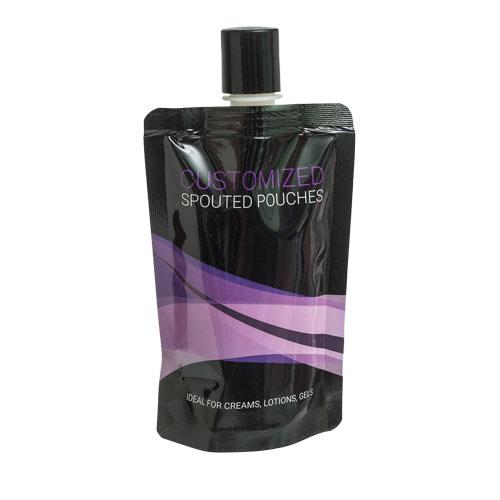

Spouted Pouches

Zipper Pouches

Slider Pouches

Premade STANDCAP Pouch for IPA hand sanitizer

Stand-up Barrier Pouches

If your requirements include barrier films that will protect your products from oxygen, light, or moisture, we can provide stand-up pouch packaging to meet the barrier properties that your products require.

Unlike some flexible packaging converters with a menu of standard materials or pouches, we’ll provide customized materials and pouches based on your specific needs. We don’t develop products and try to drive you towards them; we listen to your needs and engineer innovations that will solve your packaging challenges.

Contact us today for assistance from one of our experienced packaging engineers.

Stand Out in a Sea of Sameness

Differentiate your products and capture consumers’ attention with stand-up pouch packaging. Available with convenient features such as recloseable sliders and zippers, tear notch closures, handles, & built-in pour spouts, stand-up pouch packaging can help you drive sales of your powders, granulates, solids, and liquids.

First stand up oil pouch in the U.S. power sports industry

Converting from Rigid to Flexible Packaging?

Leading brands have turned to Glenroy when converting from rigid packaging to flexible packaging. If you’re making the transition from rigid packaging to stand-up pouch packaging, let us ease the process for you.

Stand-up Pouch & Bag Options

Pouch styles include:

- Spouted pouches or fitment pouches (including top-spouted pouches and corner-spouted pouches)

- Stand-up bottom gusset pouches (inserted or folded gussets)

- 3-side seal pouches

- Quad seal side gusset pouches (inserted or folded gussets)

- Box pouches

- Shaped pouches

Pouch closure options include:

- Spouts and fitments

- Press-to-close zippers

- Sliders (with or without end clips)

- Hooded sliders

- EASY-LOCK by APLIX®

- Other options available upon request

Pouch gusset seal types:

- K-seals

- Doyen seals

- Flat bottom seals

- Custom-designed gusset seals available upon request

Additional pouch features include:

- Rounded corners

- Mitered corners

- Tear notches

- Clear windows

- Glossy or matte finishes

- Venting

- Handle holes

- Hanger holes

- Mechanical perforating

- Wicketing

- Laser scoring or laser perforating

Fully Customized Stand-up Pouch Packaging

Our packaging engineers will work one-on-one with you to create customized stand-up pouches based upon your product’s unique formulation, usage, life cycle, and filling equipment. We incorporate a full array of technical services including advanced pouch prototyping, pouch sizing, product/package compatibility testing, burst testing, and drop testing.

With some of the most extensive in-house premade pouch converting capabilities in the industry, and with machinery that has produced award-winning stand-up pouch packaging, we offer the capabilities and expertise you need to create consumer-centric pouches that stand out.

Stand-up Pouches & Bags Frequently Asked Questions (FAQ)

Do you provide filling of premade pouches?

What is the minimum order quantity?

Does Glenroy stock premade pouches?

Can you supply prototypes?

What is vacuum testing?

What is your lead time for stand-up pouches?

What is an inserted gusset?

What is a folded gusset?

What is a tap and gland fitment?

Do you offer pouch venting?

What is wicketing?

What is toll pouching?

Do you provide toll pouching services?

Are you able to provide samples of premade pouches?

We do not supply stock pouches at this time.