Custom Finishing & Slitting

Custom Finishing & Slitting

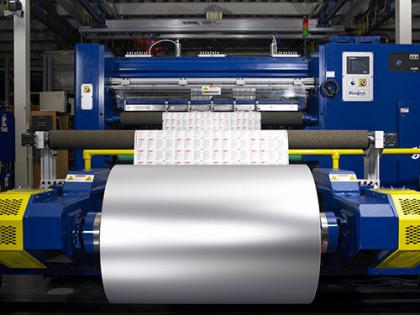

After engineering, printing, and constructing our flexible packaging films, the next step of the process is custom finishing. This step includes further inspections, slitting wide flexible packaging film rolls into specific widths determined by each customer, and preparing the final rolls of flexible packaging film for shipment with customized, customer-specified packaging and labeling styles.

If the final product is premade pouches, the finished rolls are sent to our nearby pouch converting facility and converted into pre made pouches, which then undergo further quality testing before receiving the stamp of approval.

Our knowledgeable finishing and slitting department operators have an average of 17 years of experience in the flexible packaging industry.

- Ability to rewind rolls from 3″ to 32″ in diameter

- High-speed, precision slitting in widths from 1.5″ up to 72″

- Wide range of slicing options/techniques available

- Ability to perform barcode quality scans and inline print repeat monitoring

- Custom labeling and packaging