Spouted Pouches

(Fitment Pouches)

Spouted pouches (also known as fitment pouches) are helping brands reduce their carbon footprint because they are lighter weight, use less plastic, and help lower greenhouse gas emission and fossil fuel consumption when compared to rigid packaging. Many products once limited to rigid packaging are now excellent candidates for spouted pouches.

Did you know?

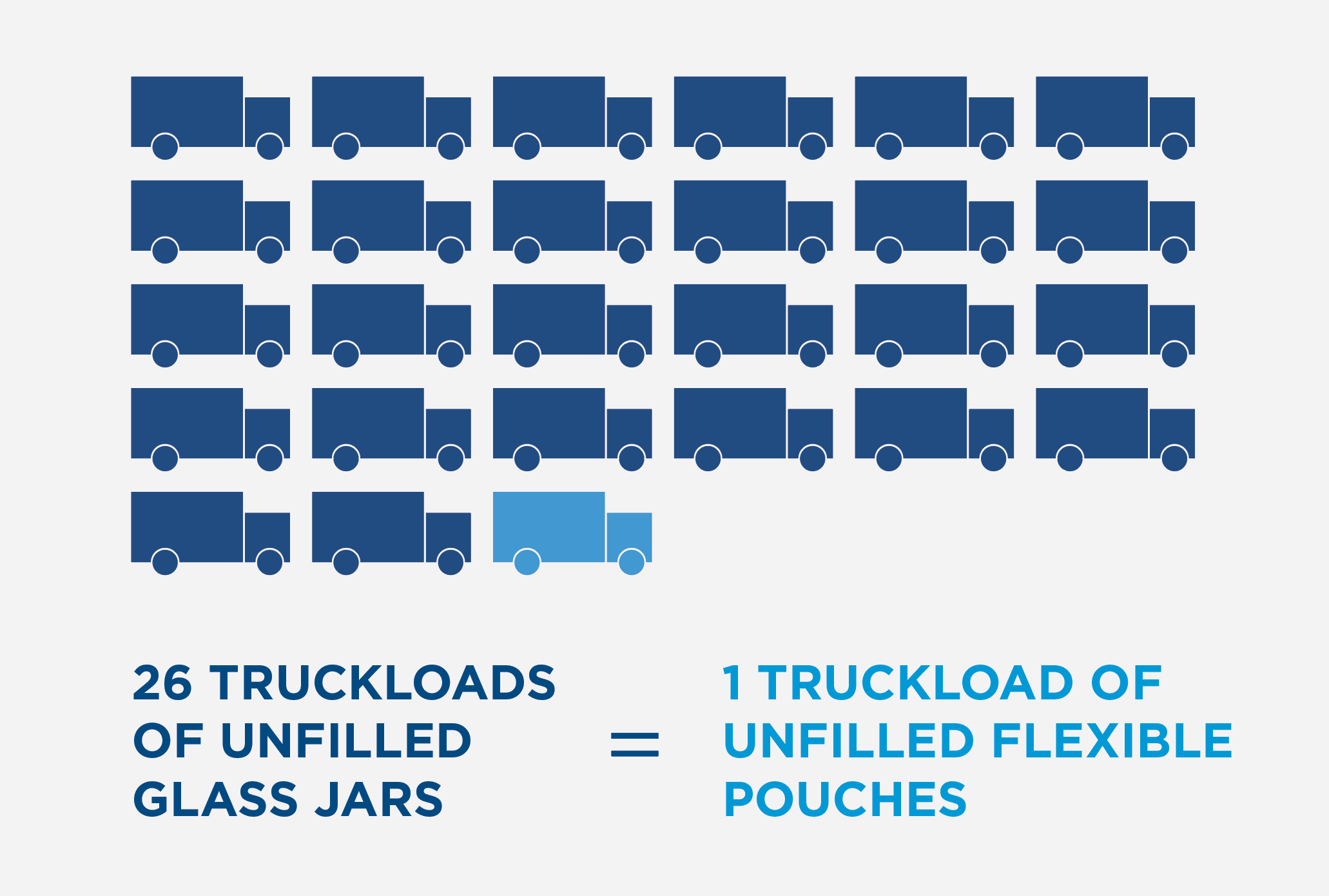

26 truckloads of unfilled glass jars is equal to 1 truckload of unfilled flexible pouches.

Eco Impact of Spouted Pouches vs. Rigid PET Bottles

According to a recent LCA study by PTIS, choosing Spouted Pouches instead of rigid PET bottles results in up to:

- 72% less plastic (by weight).

- 79% less fossil fuel consumption.

- 83% less greenhouse gas emissions.

- 62% less water usage.

- 65% less landfill waste (even when factoring in plastic recycling rates).

Spouted Pouches vs. Rigid Packaging

Contrary to popular belief, spouted pouches provide many sustainability benefits when compared to rigid packaging.

Spouted pouches:

- Allow for near total evacuation of the product (Rigid containers can leave 6 – 14% of product in packaging, while pouches can evacuate up to 99.5% of the product)

- Are conveniently lighter and more portable

- Provide shelf impact that differentiates your products from the rows of rigid packaging currently on shelves, giving you a competitive advantage

- Use approximately 60 percent less plastic than rigid plastic bottles

- Require approximately 50 percent less energy to produce

- Are much more space efficient and require less area to store in warehouses

- Generate less CO2 emissions during production

- Produce significantly less landfill waste

- Require fewer trucks for transportation—reducing fossil fuel consumption and CO2 emissions

- Provide increased printable surface area to present attention-grabbing graphics that resonate with consumers

Spouted Pouch Expertise

At Glenroy, we’ve helped leading brands convert from rigid packaging to spouted pouches. We offer not only exceptional expertise in spouted pouches, but also expansive in-house spouted pouch converting capabilities.

This allows us to produce your spouted pouches from start to finish, without outsourcing important stages of the project such as spout insertion. We’re able to produce spouted pouches with shorter lead times, while keeping full control of your pouches’ quality throughout the entire process.

Our pouch converting equipment has produced award-winning spouted pouches. We’re able to design and produce pouches with innovative shapes that prevent flex cracking, with extremely high burst strength and the ability to withstand even the most rigorous drop testing.

Manufactured by Glenroy, the SoChatti Chocolate spouted pouch received a special exemption from Amazon to enable year-round fulfillment without temperature regulation or waste.

Spouted Pouches for Hand Sanitizer

Many brands and companies are turning to flexible packaging to package hand sanitizer products. As experts in high barrier applications since 1965, we’re here to help with various spouted pouch solutions:

- Corner spouted pouches

- Top spouted pouches

- Screw caps, disc caps, flip-top caps, and more closures available on corner & top spouted premade pouches

- Premade STANDCAP Pouches

Spouted Pouch Prototyping

Our packaging engineers are experts at listening to your needs and crafting innovative prototypes that incorporate convenient features such as handles to facilitate easy pouring and high-barrier formats to meet the requirements of your product. We’re uniquely able to engineer and produce spouted pouch prototypes custom-printed with your graphics, so your prototypes show a more accurate presentation of the final package.

We have access to a large variety of spouts and fitments for liquids, powders, gels, and granulates.

Award-winning EcoVue FlexPac® for Ultrasound Gel

Fitment/closure Options

We offer a wide range of options for fitments & closures with our pouches. A few examples include:

- Corner-mounted spouts

- Top-mounted spouts

- QuickFlip spouts

- Disc-cap closures

- Screw-cap closures

- Push-pull closures

- Inverted Sierra closure

Learn How Glenroy Developed the First Spouted Pouch in the U.S. Power Sports Industry

Six Pitfalls to Avoid When Choosing Stand up Pouches for Liquids

Spouted Pouch Testing

We perform a number of rigorous tests on spouted pouches to ensure your pouches will perform throughout the life cycle of your product. The various tests we perform include:

- Interlayer adhesion testing

- Seal strength testing

- Drop testing

- Burst testing

- Tensile testing

- Product package compatibility testing

- Compression testing

- Puncture resistance testing

Spouted Pouch Applications

We have the technology and expertise to manufacture spouted pouches for a wide array of products, including:

- Condiments

- Dressings

- Marinades

- Spreads

- Jams

- Sauces

- Syrups

- Baby food

- Yogurt

- Alcoholic beverages

- Lotions

- Conditioners

- Shampoos

- Gels

- Creams

- Ointments

- Oil

- Lubricants

- Laundry detergent

- Cleaners

- Sanitizers

- Stain removers

- Insect repellents

- Bath crystals

- Dish soap

- Hand soap